The out-of-stock dilemma is a significant challenge for e-commerce websites. Out-of-stock items lead to lost sales, frustrated customers, and damage to brand reputation. Effectively managing inventory and implementing strategies to mitigate the impact of stockouts is crucial for maintaining a competitive edge in the online marketplace. This article will explore the various factors contributing to the out-of-stock problem and present winning strategies for e-commerce websites to navigate these challenges and minimize their negative consequences.

From accurate demand forecasting and efficient inventory management to proactive customer communication and creative sales recovery techniques, there are numerous approaches e-commerce businesses can adopt. By understanding the underlying causes of stockouts and implementing the appropriate strategies, businesses can transform this challenge into an opportunity to enhance customer loyalty and drive sales growth. Discover how to turn the out-of-stock dilemma into a winning formula for your e-commerce website.

Understanding the Impact of Out-of-Stock Products

Out-of-stock items represent a significant challenge for e-commerce businesses. Lost sales are an immediate and obvious consequence. When a customer can’t purchase their desired product, they often turn to competitors, leading to decreased revenue and potentially impacting customer loyalty.

Beyond immediate sales losses, stockouts damage a brand’s reputation. Customers may perceive the business as unreliable or disorganized. This negative perception can affect future purchasing decisions and hinder the growth of the business.

Furthermore, out-of-stocks can negatively impact customer satisfaction. A frustrated customer encountering an unavailable product is less likely to have a positive shopping experience. This can lead to negative reviews and diminished word-of-mouth referrals.

Finally, consistent stockouts can complicate inventory management. They make it difficult to accurately forecast demand and optimize stock levels, creating a cycle of inefficiency.

Proactive Measures: Preventing Stockouts

Preventing stockouts requires a proactive approach to inventory management. Implementing robust systems and strategies can significantly minimize the occurrence of these disruptive events.

Demand Forecasting

Accurate demand forecasting is crucial. Analyze historical sales data, seasonal trends, and market influences to predict future demand. Utilizing sophisticated forecasting software can enhance accuracy and provide valuable insights.

Inventory Control

Maintain real-time visibility into inventory levels. Implement an inventory management system that tracks stock in real-time, providing alerts for low stock levels and automating reordering processes. Regularly audit physical inventory to ensure accuracy.

Supplier Relationships

Cultivate strong relationships with reliable suppliers. Establish clear communication channels and service level agreements. Diversifying suppliers can mitigate risks associated with supply chain disruptions.

Safety Stock

Maintain a safety stock buffer to account for unexpected demand spikes or delays in supply. Calculating the appropriate safety stock level requires careful consideration of lead times and demand variability.

Communicating with Customers about Out-of-Stock Items

Transparency is key when dealing with out-of-stock situations. Clearly communicate the product’s unavailability on the product page. Avoid misleading customers by allowing them to add the item to their cart only to discover it’s out of stock during checkout.

Offer proactive communication. If a customer attempts to purchase an out-of-stock item, provide an immediate notification. This could be a pop-up message or an email confirming the item’s unavailability. Allow customers to sign up for back-in-stock notifications and clearly communicate the estimated restock date, if known.

Personalized communication can enhance the customer experience. If possible, segment customers based on their purchase history or browsing behavior and tailor the out-of-stock message accordingly. For example, offer personalized recommendations for similar products.

Maintain consistent communication across all channels. Ensure your customer service team is prepared to answer questions about out-of-stock items and provide accurate information.

Managing Customer Expectations

Managing customer expectations regarding out-of-stock items is crucial for maintaining customer satisfaction and loyalty. Transparency is key. Clearly communicate the product’s unavailability and provide realistic timelines, if possible.

Avoid overly optimistic estimates that could lead to disappointment. If the restock date is uncertain, it’s better to acknowledge that than provide inaccurate information. Consider offering pre-orders or back-in-stock notifications to keep customers engaged and informed.

Proactive communication demonstrates respect for the customer’s time and builds trust. Explain the reason for the stockout, whether it’s due to high demand, supply chain disruptions, or other factors. This openness can foster understanding and mitigate negative perceptions.

Offering exclusive discounts or promotions to customers who experience an out-of-stock situation can also help to soften the blow and encourage future purchases.

Offering Alternative Products or Solutions

When a product is out of stock, offering alternatives can significantly mitigate customer disappointment and potentially save a sale. Suggesting similar items keeps the customer engaged with your site and demonstrates proactive customer service.

Present alternatives strategically. Display them prominently on the product page of the unavailable item. Highlight key features and benefits of the alternative product, emphasizing how it compares to the originally sought-after item. Consider factors like price, functionality, and brand to ensure relevant recommendations.

Beyond product suggestions, consider other solutions. Back-in-stock notifications allow customers to express their interest and receive an alert when the item becomes available. This provides a valuable service while capturing potential future sales. Alternatively, offering a pre-order option for popular items can satisfy customer demand and provide insights into future inventory needs.

Back-in-Stock Notifications and Alerts

A key strategy for managing out-of-stock situations and maintaining customer engagement involves implementing a robust back-in-stock notification system. This allows interested customers to sign up for alerts when a desired product becomes available again. This proactive approach mitigates the frustration of encountering out-of-stock items and encourages customers to return to the website.

Effective back-in-stock notifications require a user-friendly interface for easy sign-up. Clearly labeled buttons or forms adjacent to out-of-stock products simplify the process. The system should capture necessary customer information, such as email address, and clearly communicate the expected timeframe for restocking (if known).

Automated alerts should be triggered immediately upon product availability. These alerts should contain essential product information, including name, image, and price. A direct link to the product page allows for a seamless purchase experience. This prompt notification capitalizes on customer interest while it’s still high, minimizing potential lost sales.

Utilizing Pre-Orders Effectively

Pre-orders offer a powerful tool for managing demand when products are temporarily out of stock. They allow customers to reserve an item and guarantee its delivery once back in stock. This strategy benefits both businesses and consumers.

For businesses, pre-orders provide valuable insights into demand forecasting. They reveal which products are highly sought after and help in making informed decisions about inventory replenishment. This minimizes the risk of overstocking or understocking items. Pre-orders also generate upfront revenue, which can be utilized to finance production or manage cash flow.

Customers benefit from pre-orders by securing a product they desire, especially if it is in high demand or a limited edition. This eliminates the frustration of encountering the dreaded “out of stock” message. A well-structured pre-order system builds customer loyalty and strengthens brand engagement by creating a sense of exclusivity and anticipation.

Key considerations for successful pre-order implementation include clear communication regarding estimated shipping dates and transparent terms and conditions. Managing customer expectations is crucial to avoid disappointment and maintain a positive customer experience.

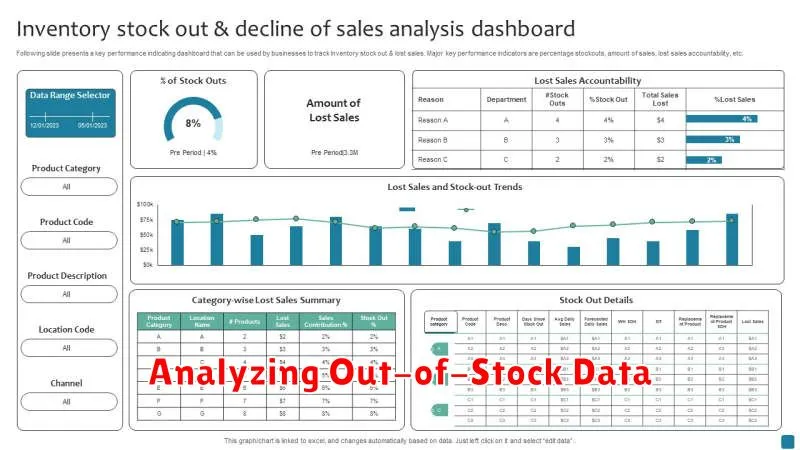

Analyzing Out-of-Stock Data

Understanding the reasons behind stockouts is crucial for developing effective prevention strategies. Data analysis plays a vital role in this process. By examining out-of-stock data, businesses can identify trends and patterns that contribute to inventory issues.

Key metrics to track include the frequency of stockouts for each product, the duration of these stockouts, and the lost sales associated with each instance. This information can highlight problematic products and reveal underlying issues within the supply chain.

For example, frequently out-of-stock items may indicate inaccurate demand forecasting, supplier delays, or insufficient safety stock levels. Analyzing these metrics alongside sales data and marketing campaign performance can provide a holistic view of the contributing factors.

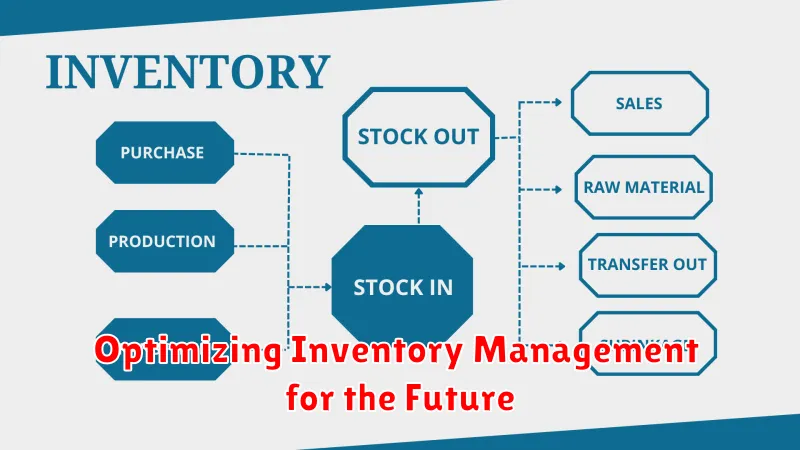

Optimizing Inventory Management for the Future

Proactive inventory management is crucial for minimizing future stockouts. Demand forecasting plays a key role, utilizing historical data, trend analysis, and seasonality patterns to predict future demand. Sophisticated software solutions can automate this process and provide valuable insights.

Safety stock acts as a buffer against unforeseen demand spikes or supply chain disruptions. Determining the appropriate safety stock level involves balancing holding costs against the risk of stockouts. Regular review and adjustment of safety stock levels are essential for optimal performance.

Supplier relationship management is another critical factor. Establishing strong relationships with reliable suppliers ensures timely deliveries and open communication. Negotiating favorable terms and exploring backup suppliers can further mitigate supply chain risks.

Finally, implementing a robust inventory management system provides real-time visibility into stock levels, allowing for proactive adjustments and informed decision-making. This includes accurate tracking of inventory across all locations and integration with sales channels.